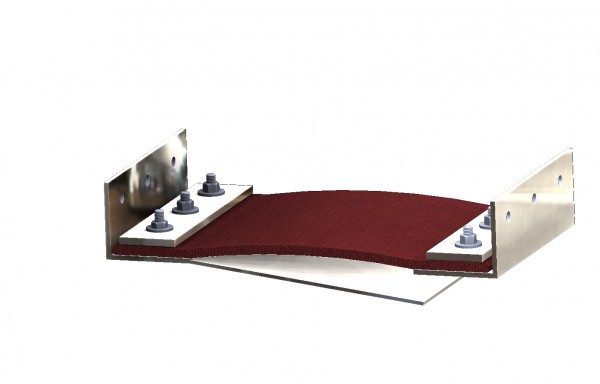

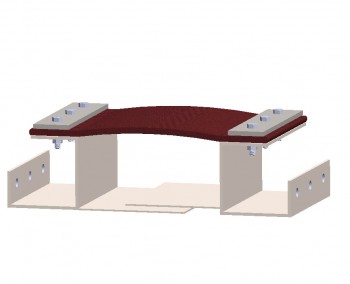

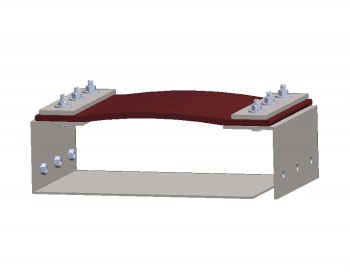

The Leg-Out-style ductwork frame uses a fabricated angle frame with a composite belt cover attached directly to the frame using studs and backing bars or heavy-duty band clamps. This style of expansion joint can be assembled with an internal flow liner for abrasion protection. The mounting holes are easily accessible for quick installation and the frame can be fabricated from carbon steel, stainless steel, or other alloys.

Accessories

-

Flow Liner

All expansion joints can be supplied with various configurations of flow liners. Flow Liners can be supplied as bolt-in unit design, single, tapered, overlapping, and floating. The primary purpose of flow liners is protection of the internal insulating materials from abrasives in the gas flow. They are also used to secure the internal accumulation pillow in place as well as to provide a laminar flow in the area of the expansion joint. Flow liners need to be designed to allow full system design movements while providing the necessary protection and support. Many materials of construction are available including carbon steel, stainless steel, Corten, AR Plate, and special alloys. Check with FS Products to see how flow liners can increase the life of your expansion joints.

-

Gasket

Gasket are recommended for any metal to metal installation. We stock several widths of fiberglass gasket tape as well as PTFE coated fiberglass products. Our extruded PTFE gasket tape is ideal for fabric to metal installations or when a highly compressible, chemical resistant seal is needed. Let us provide all of the gaskets required for your expansion joint installation to avoid costly delays and misplaced parts needed during installation.

-

Fasteners

Flexible Specialty Products can provide any necessary mounting fastener for your expansion joint application. We will properly size the fasteners and provide standard grade or any specialty fastener required. The fasteners will be packaged with the expansion joint shipment to assure the fasteners will be on-site when needed to avoid costly delays or misplaced parts.