Expansion Joint Parts Breakdown

Flexible Specialty Products’ fabric expansion joints parts are used to isolate movements or vibration in ductwork, which reduces transmission to adjoining ducts, pipes, vessels, or supports in the system. The flexible fabric element spans between two frameworks or two mating flanges of the ductwork to provide movement allowance in various directions. Fabric expansion joints are ideal for this application due to their extreme flexibility, chemical resistance, and ability to withstand high temperatures. Fabric expansion joints can be divided into two basic categories; Flat Belt Frame Style and U-Joint Formed Flange (or frameless). Flat Belt Frame Style expansion joints can be designed for temperatures in excess of 2000ºF while the simpler U-Joint Formed Flange is a flexible connector that can withstand temperatures up to 1000oF. Below is a description of various expansion joint parts that are used for the construction of these styles of products. Flexible Specialty Products will custom design the type of expansion joint that works best for your application along with the required accessories.

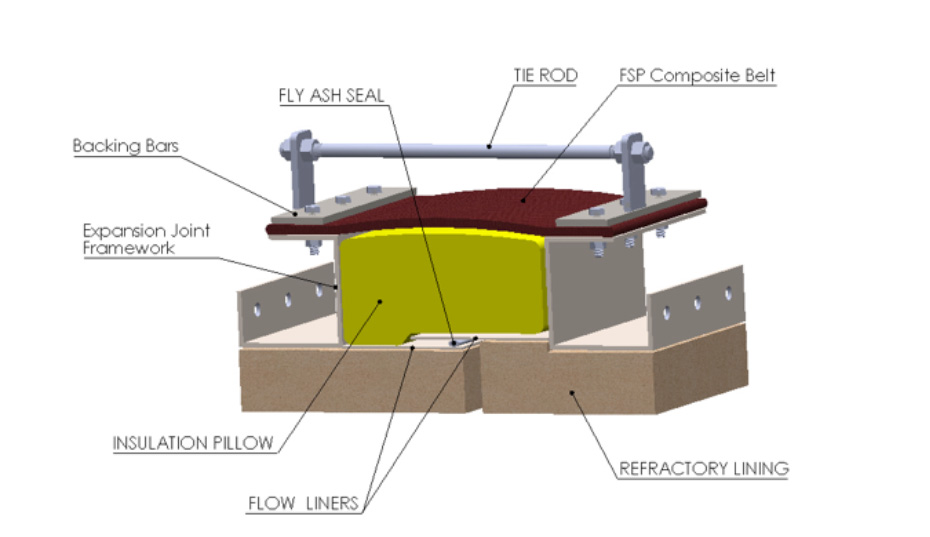

Flat Belt Frame Style

Expansion Joint Framework: The expansion joint framework can be manufactured in various configurations using carbon steel, stainless steel, or other alloys. The purpose of the framework is to provide a sturdy assembly with a mounting surface for the fabric composite belt as well as a means for mounting the assembly.

FSP Composite Belt: The outer FSP Composite Belt provides the gas seal of the expansion joint. It is generally composed of an external gas barrier along with various layers of internal insulation blanket and high-temperature cloth. This composite belt is designed to provide protection from the design temperature, movements, chemical attack, flutter, and abrasion. FSP custom designs composite belts to meet the needs of the customer, but we also have standard designs for 800ºF, 1000ºF, 1300ºF and 1800ºF.

Backing Bars: Backing bars, also known as clamp bars, hold the flexible composite belt to the framework. These are typically 1/4” or 3/8” thick flat bars with holes pre-punched to match the framework bolt pattern. The hole spacing and bolt size should provide the proper clamping force needed to seal the composite belt to the framework. Various alloys and specialty paint systems can be used to protect the backing bars from corrosion.

Flow Liners: Flow liners can be provided as a single liner, overlapping (telescoping) liners, or floating liners. Flow liners have the main purpose of protecting the internal insulating layers from abrasion and erosion. They also help to provide a more laminar flow through the expansion joint area and provide an internal cavity area to install an insulation pillow. An array of materials and thicknesses are available depending on the specific application.

Insulation Pillow: Insulation pillows are also sometimes called accumulation pillows or insulation bolsters. They are manufactured using fiberglass or ceramic insulation blanket and are layered to provide additional thickness. Insulation pillows are typically wrapped in a stainless steel mesh or high temperature fabric before installation. They provide additional temperature protection of the external composite belt as well as fill the internal joint cavity to reduce particulate build up. Other purposes include sound abatement and reduction of flutter for high velocity applications.

Refractory Lining: Castable refractory linings can be mounted to a Flat Belt Frame Style expansion joint by adding refractory anchors to the flow liners and pouring a castable lining to the interior side of the expansion joint. Refractory linings are typically used for very high temperature applications or when extreme abrasion may be present. Other options include fiber modules that can be mounted to the flow liners in a similar way to provide temperature protection up to 2400ºF.

Tie Rods: Tie rods are provided to limit the amount of movement the expansion joint can be subjected to during normal and upset conditions. This helps to prevent over-extension of the fabric, which will cause damage to the outer composite belt.

Fly Ash Seal: The fly ash seal is a compressible seal that helps to prevent ash or particulate from entering the expansion joint cavity. A seal can be made of metal or fabric rope and needs to allow required movements during operation. The seal is mounted between two overlapping flow liners.

Drains (Not Shown): Various types and sizes of drains can be incorporated into a frame design to allow draining of liquid in the system due to condensate build up or from a wash down during maintenance.

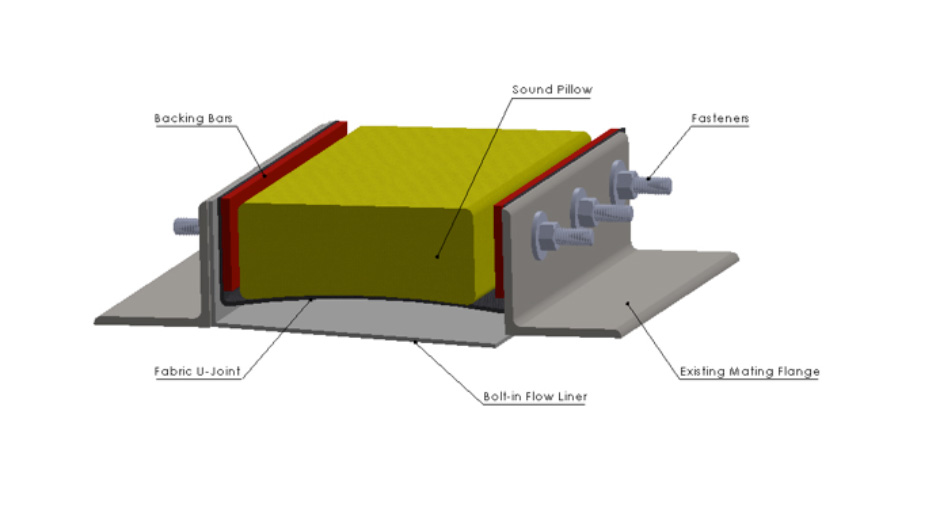

U-Joint Formed Flange

Fabric U-Joint: The flexible gas barrier element is provided with formed integral flanges to allow the Fabric U-Joint to slip between two adjoining duct or pipe flanges. The fabric used should be rated for full system design temperature and be able to withstand required chemical attack and abrasion.

Backing Bars: Backing bars are provided to mount, or clamp, the fabric element to the adjoining flanges. No framework is supplied for this type of joint and can easily be installed by slipping the backing bars over the Fabric U-Joint and mounting the fasteners. The backing bars can be provided as flat bar, angle, or channel as required to provide the proper stiffness and sealing pressure to reduce leakage.

Bolt-in Flow Liner: A Bolt-in Flow Liner is required when there is an abrasive flow media or to maintain the cross-section open area under high negative operating pressures. Flow liners can be provided as straight or tapered to help provide a laminar gas flow. Holes are pre-punched to match the adjoining flange to allow simple installation.

Sound Pillow: Sound pillows provide sound attenuation for applications requiring sound abatement such as large blowers. This external accessory is manufactured using high density insulation that is encapsulated with weatherproof fabric. Sound pillows are easily mounted by wrapping the pillow around the fabric element and attaching the ends with the hook and loop fastening system provided.

Fasteners: FS Products can provide all of the required fasteners needed for installing expansion joints on site. This reduces delays due to misplaced or missing parts needed to complete the installation. We always provide 5% excess fasteners to avoid shortages from dropped or defective fasteners.

Mating Flanges: The mating flanges are rolled/fabricated angles or plate that are welded to the ductwork or piping to allow mounting of the Fabric U-Joint. These are often already in-place, but FS Products can provide a turn-key solution when a new expansion joint is added or replacement of flanges is required. We will manufacture and test fit the Fabric U-Joint assembly to make sure there will be no problems in the field.