Gas Turbine Expansion Joints

Flexible Specialty Products manufactures gas turbine expansion joints to meet the challenges of the high velocity gases produced at high temperatures in this specialized environment. FSP has the engineering experience and fabrication knowledge to design and build a turbine inlet or outlet expansion joint to your exact specifications.

FSP uses a PTFE/fiberglass outer composite gas barrier designed to accommodate the stresses, flutter, and temperatures that a gas turbine produces. The rapid temperature increases that a turbine expansion joint experiences can cause distortion and lateral misalignment. FSP expansion joints can accommodate the demands required of a turbine expansion joint.

There are three basic types of turbine expansion joints, Hot-Hot, Hot-Cold, and Cold-Cold. The type is dictated by the individual installation and each requires specific materials of construction and design of the expansion joint. There are many available designs manufactured by FSP for turbine inlets and turbine exhaust expansion joints. Below are some typical example to show the basic installation.

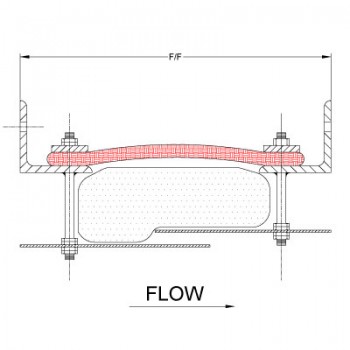

Cold to Cold – Cold to Cold configurations use threaded rod to attach internal flow liners and no part of the mounting frame is subjected directly to the hot gas flow. This frame type typically uses a carbon steel framework on each side with stainless steel flow liners. Both sides of adjacent ductwork have internal insulation and internal shrouds that tie directly into the expansion joint’s flow liners.

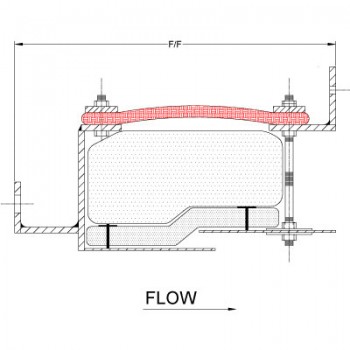

Hot to Cold – Hot to Cold Turbine expansion joints have a stainless steel or alloy steel framework on the hot side and a carbon steel frame on the cold side. The two expansion joint frameworks are designed to accommodate two different bolt patterns and provide the required protection of the frameworks and outer composite belt. Drains can be added to accommodate water washing of the turbine or ductwork. Internal liners can be welded to the hot side while they are typically suspended with rods on the cold side to provide an internal laminar flow surface.

Showing all 3 results

-

Custom Cold-Cold Gas Turbine Expansion Joints

Cold to Cold gas turbine expansion joint configurations use threaded rods to attach internal flow liners. No part of the mounting frame is subjected directly to the hot gas flow. This frame type typically uses a carbon steel framework on each side with stainless steel flow liners. Both sides of adjacent ductwork have internal insulation and internal shrouds that tie directly into the expansion joint’s flow liners.

-

Custom Hot-Cold Gas Turbine Expansion Joints

Hot to Cold gas turbine expansion joints have a stainless steel or alloy steel framework on the hot side and a carbon steel frame on the cold side. The two expansion joint frameworks are designed to accommodate two different bolt patterns and provide the required protection of the frameworks and outer composite belt. Drains can be added to accommodate water washing of the turbine or ductwork. Internal liners can be welded to the hot side while they are typically suspended with rods on the cold side to provide an internal laminar flow surface.

-

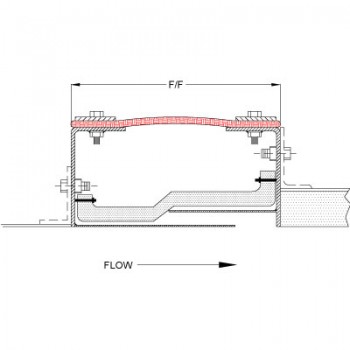

Custom Hot-Hot Gas Turbine Expansion Joints

Hot to Hot-type gas turbine expansion joints have frameworks on the upstream and downstream sides that are exposed to the full temperature of the gas flow. The upstream and downstream frames can accommodate two different bolt patterns as needed and are fabricated from stainless steel or other alloy designed to handle full design temperature. This type of framework can have many configurations that can allow slip-in installation or access to all fasteners for ease of maintenance.