Fabric Expansion Joints

Showing 1–10 of 14 results

-

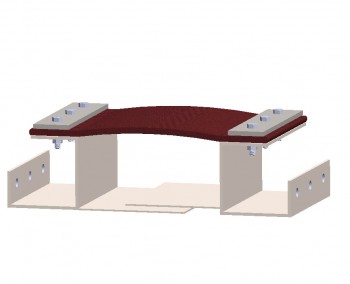

Backing Bars

Backing bars, or clamp bars, are steel bars or angles used to mount or clamp the fabric to the frame work or duct flange. FS products manufactures backing bars in a variety of materials and thickness as required based on the specific application. The backing bars are shipped as full rings or picture frames when practical. Holes are pre-punched to match the adjoining ductwork to allow quick and easy installation of our U-Joint Formed Flange expansion joints. Backing bars are typically shipped painted with our standard high-temperature silver primer, but custom coatings and galvanizing can also be applied.

-

Accumulation Pillow

Accumlation pillows or insulation bolsters are manufactured out of fiberglass or ceramic high density blanket. They can be wrapped in stainless steel mesh or a variety high temperature fabrics. Multiple layers provide the thickness required to fill the expansion joint cavity of a Flat Belt Frame Style expansion joint. The primary purpose is to fill the expansion joint cavity, which reduces particulate build-up. This build-up of ash or particulate can reduce the flexibility of the expansion joint. The pillow can also be used to provide additional insulation or for sound abatement as well as to reduce flutter in high velocity applications.

-

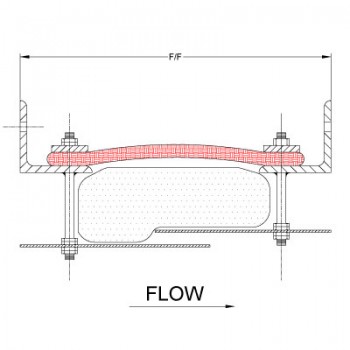

Flow Liner

All expansion joints can be supplied with various configurations of flow liners. Flow Liners can be supplied as bolt-in unit design, single, tapered, overlapping, and floating. The primary purpose of flow liners is protection of the internal insulating materials from abrasives in the gas flow. They are also used to secure the internal accumulation pillow in place as well as to provide a laminar flow in the area of the expansion joint. Flow liners need to be designed to allow full system design movements while providing the necessary protection and support. Many materials of construction are available including carbon steel, stainless steel, Corten, AR Plate, and special alloys. Check with FS Products to see how flow liners can increase the life of your expansion joints.

-

Gasket

Gasket are recommended for any metal to metal installation. We stock several widths of fiberglass gasket tape as well as PTFE coated fiberglass products. Our extruded PTFE gasket tape is ideal for fabric to metal installations or when a highly compressible, chemical resistant seal is needed. Let us provide all of the gaskets required for your expansion joint installation to avoid costly delays and misplaced parts needed during installation.

-

Fasteners

Flexible Specialty Products can provide any necessary mounting fastener for your expansion joint application. We will properly size the fasteners and provide standard grade or any specialty fastener required. The fasteners will be packaged with the expansion joint shipment to assure the fasteners will be on-site when needed to avoid costly delays or misplaced parts.

-

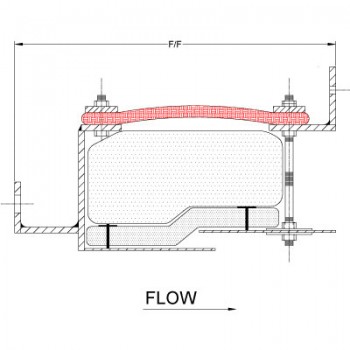

Custom Cold-Cold Gas Turbine Expansion Joints

Cold to Cold gas turbine expansion joint configurations use threaded rods to attach internal flow liners. No part of the mounting frame is subjected directly to the hot gas flow. This frame type typically uses a carbon steel framework on each side with stainless steel flow liners. Both sides of adjacent ductwork have internal insulation and internal shrouds that tie directly into the expansion joint’s flow liners.

-

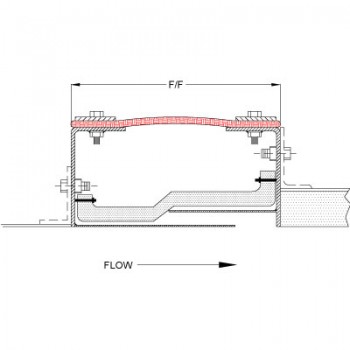

Custom Hot-Cold Gas Turbine Expansion Joints

Hot to Cold gas turbine expansion joints have a stainless steel or alloy steel framework on the hot side and a carbon steel frame on the cold side. The two expansion joint frameworks are designed to accommodate two different bolt patterns and provide the required protection of the frameworks and outer composite belt. Drains can be added to accommodate water washing of the turbine or ductwork. Internal liners can be welded to the hot side while they are typically suspended with rods on the cold side to provide an internal laminar flow surface.

-

Custom Hot-Hot Gas Turbine Expansion Joints

Hot to Hot-type gas turbine expansion joints have frameworks on the upstream and downstream sides that are exposed to the full temperature of the gas flow. The upstream and downstream frames can accommodate two different bolt patterns as needed and are fabricated from stainless steel or other alloy designed to handle full design temperature. This type of framework can have many configurations that can allow slip-in installation or access to all fasteners for ease of maintenance.

-

Insulation Pillows

-

J-Frame-Style Ductwork

- Slip-In Installation

- Excellent Access to All Fasteners

- Design Temperatures to 2200F